Internet of Things or IoT simply refers to the connection of devices for data collection, analysis, and sharing. The building blocks of IoT are data-gathering devices, connectivity, data analytics capability, and user interface. An example of IoT technology set-up is sensors and cameras, equipped with wireless connectivity which is then processed and accessed via the internet through smartphones.

These characteristics of IoT leadto the proliferation of smart devices in different field of business andconsumerism. Its main attraction is that internet-enabled machines tend to workwithout direct human interventions. Imagine controlling your appliances throughyour phone while overlooking your work from home or directing your staff whileon a vacation. Life is made easy with smart devices. Connectivity is the assetof IoT devices that indulges more consumers and businesses to take a leap fromits traditional operation.

However, IoT has so much more tooffer! One key feature of this technology is data analysis. While moreconsumers are likely satisfied with the direct service rendered by the smartdevices, IoT is moving slowly in the utilization of “data analytics” assolutions to real-world problems in the community as well as in the industry.IoT through data analysis adds more value to the smart gadgets in place onhomes, streets, cars, parking lots, agriculture, business centers, productionlines, and the list goes on!

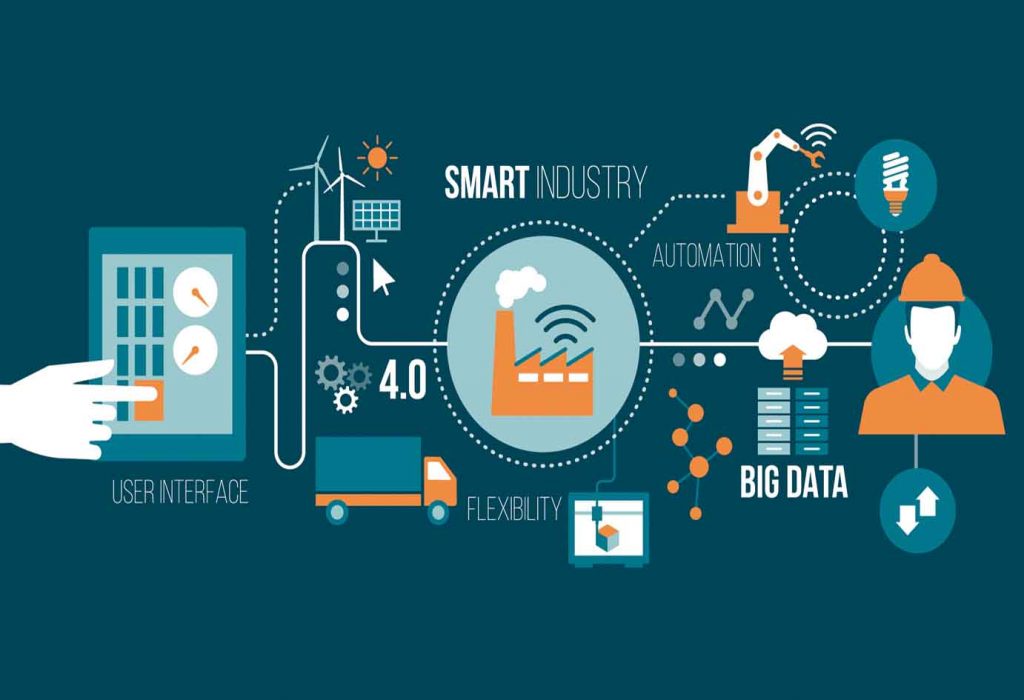

The characteristics of IoT can beintegrated with Industry 4.0 wherein the main goal is to accustom automationand data connectivity in the industrial ecosystem. This goal encouragesinitiatives in advanced manufacturing and optimization operation. Hence, IoT isa promising technology for Industry 4.0.

According to de Backer, Mancini, and Sharma, Industry 4.0 converges the following technologies: machine inter-connectivity, analytics and intelligence, advanced production methods, and human-machine interaction in the manufacturing sector.

- Machine connectivity involves machine to machine (M2M) communication, machine to sensor connectivity, and cloud technology.

- Analytics and intelligence pertaining to big data analytics and learning-based automation work.

- Advanced production methods include technology to improve manufacturing techniques.

- Human-machine interfaces such as touch interface, augmented-reality tools, and collaborative robots.

One major advantage of theemergence of IoT in the industrial operation the monitoring and adjusting ofmachines in a remote central control room. The processes involved in thecontrol room are hardware data collection, software analyses and decisions, andremote user manipulation. The sensing hardware collects and monitors data. Thesecurrent and historical data are software analyzed and process to facilitate parameter-basedmodels for decision-making.

These methods lead to labor efficiency,yield increased, yield tracking, throughput traceability, and quality enhancement.Other than machine data-driven real-time adjustments, a lot more can be done onthe collected data. To name a few, data can be used for preventive maintenance ofmachines, predicting parts replacement, information lost productivity andprofits.

Data analytics and processing ofIoT- gathered information can be taken advantage of in the Industry 4.0, butthe industrial IoT adoption has not accelerated these past years. In fact, few large-scaleindustries are adopting IoT projects in their businesses. And for somecompanies that adopted IoT in their operations, a report from McKinsey GlobalInstitute says that there is limited data usage from IoT devices for real-timedeployments and large-scale project. Business managers and leaders arereluctant to use IoT data analytics for reasons such as accountability issues,lack of capable staff, lack of trust in the decision-making process, andattachment to the old-style method and experiences. IoT security concerns are alsoa challenge in the integration of IoT in industries since complete securityinitiatives should be adopted to do away with its network vulnerabilities. Furthermore,the lack of IoT standards for seamless connectivity and transmission is onegeneral concern that posed doubt in the adoption of IoT.

If there is one field that couldfully adopt what IoT could offer, it’s the manufacturing industry! Campaigns inthe used of IoT in the industrial application has to be intensified andinnovations on the implementation strategies should be adopted in order to convincemanufacturers of the importance of IoT in the full implementation of Industry4.0. IoT drivers should focus on developing and enhancing data analytics applicationsof IoT in the financial, business operations, and convenience. Moreover, maximize design on the specificoperation to create more usability in all departments and sectors. Technicaland analytical training on IoT associated technology should be initiated somore workforce will be involved the spreading of this one enormous technology. Inthis way, IoT will become a way of life in the manufacturing industry.